Stainless Steel Tube Market Analysis 2020

by:East King

2020-08-29

Galling, typically called cold welding, is a type of extreme adhesive wear, which might occur when two metal surfaces are in relative movement to each other and under heavy strain. Austenitic stainless steel fasteners are significantly susceptible to string galling, though different alloys that self-generate a protective oxide floor film, such as aluminium and titanium, are additionally vulnerable. Under high contact-drive sliding, this oxide can be deformed, damaged, and removed from components of the component, exposing the bare reactive metallic. When the 2 surfaces are of the identical materials, these exposed surfaces can simply fuse. Separation of the two surfaces may end up in floor tearing and even complete seizure of metallic elements or fasteners.

Unlike carbon steel, stainless steels do not undergo uniform corrosion when uncovered to wet environments. Unprotected carbon steel rusts readily when uncovered to a mixture of air and moisture. In addition, as iron oxide occupies a bigger quantity than the unique steel, this layer expands and tends to flake and fall away, exposing the underlying steel to further assault. This passive film prevents further corrosion by blocking oxygen diffusion to the steel floor and thus prevents corrosion from spreading into the majority of the metal.

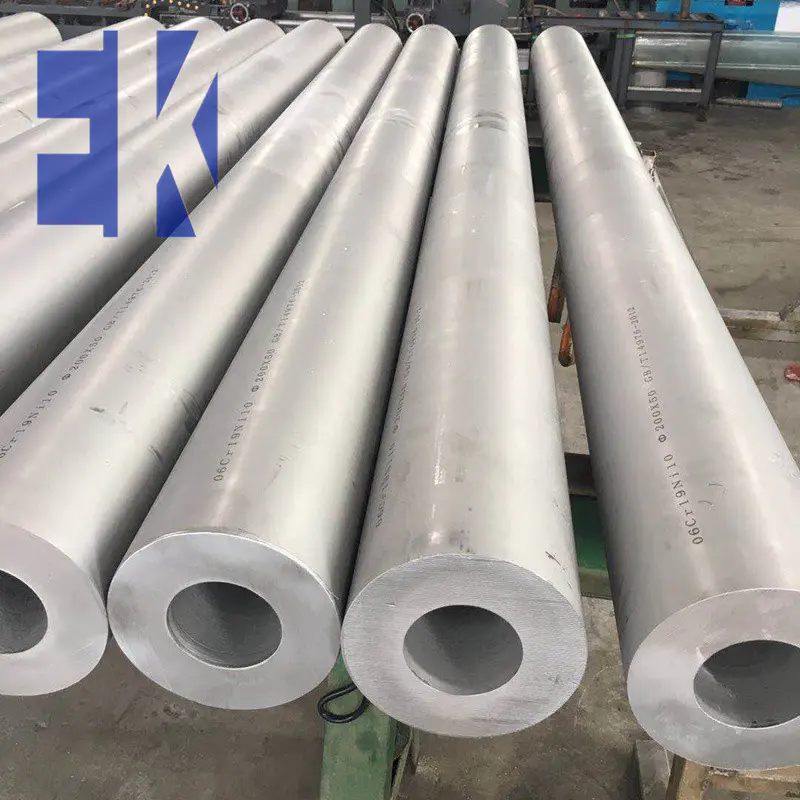

For an overview of product choices view our stainless steel products line card. Copper tube thermal conductivity is 100W/m℃, stainless steel tube is 13W/m℃, which is able to have an effect on the general warmth switch coefficient.

However, the wall thickness of stainless steel pipe may be lowered by 0.5~0.8mm, while copper pipe can't be lower than 1.2mm due to the power, erosion put on and different reasons. Due to the sleek inner floor of stainless steel tube, the boundary laminar layer thickness turns into thin, which not solely enhance the heat switch, and likewise improve the performance of anti fouling. In order to get rid of the welding stress, do the heat treatment with 1050 ℃ in the shielding gasoline. And adopts differential stress leak take a look at, pressure test to 10 mpa, 5 minutes with out stress drop.

Stainless steels have a protracted historical past of application involved with water because of their excellent corrosion resistance. Applications include a variety of conditions together with plumbing, potable water and wastewater remedy, desalination, and brine treatment. Types 304 and 316 stainless steels are commonplace supplies of development in contact with water. However, with rising chloride contents, larger alloyed stainless steels such as Type 2205 and super austenitic and super duplex stainless steels are used.

Custom message