| Stainless Steel Perforated Sheet & Plate | ||||||||

| Product Name | Perforated stainless steel plate | |||||||

| Grade | 304.304L,316,316L,321,310,309L,317 | |||||||

| Standard | JIS, AISI, ASTM, DIN, GB, etc. | |||||||

| Length | 1000-6000mm,according to your requirements | |||||||

| Width | 1000-2000mm,according to your requirements | |||||||

| Thickness | 0.3-8mm,according to your requirements | |||||||

| Mesh Aperture | 1-6mm,according to your requirements | |||||||

| Hole Distance | 1-10mm,according to your requirements | |||||||

| Form | Perforated | |||||||

| MOQ | 1 TON | |||||||

| Hole Type | Circle, Square, Hexagon, Scale, Rectangle, Triangle, Cross, Slotted | |||||||

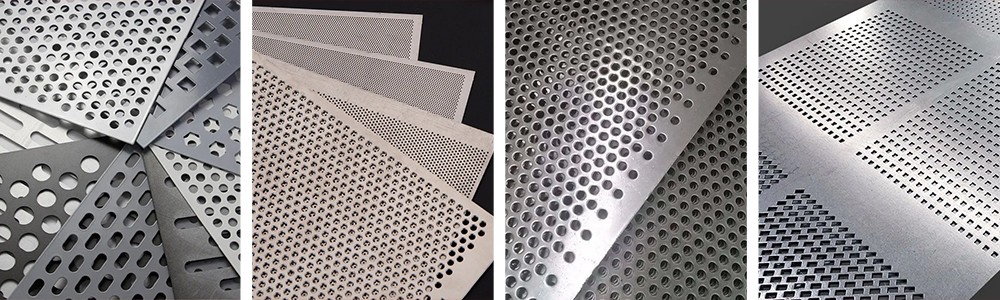

Product area display

| Mechanical Property | |||||

| ASTM | TS(Mpa)≥ | YS(Mpa)≥ | EL(%)≥ | Hardness | |

| HB | HRB | ||||

| 201 | 520 | 275 | 40 | 241 | 100 |

| 202 | 520 | 275 | 40 | 207 | 95 |

| 301 | 520 | 205 | 40 | 207 | 95 |

| 304 | 520 | 205 | 40 | 20 | 90 |

| 304L | 480 | 175 | 40 | 187 | 90 |

| 309S | 520 | 205 | 40 | 187 | 90 |

| 310 | 520 | 205 | 40 | 187 | 90 |

| 310S | 520 | 205 | 40 | 187 | 90 |

| 316 | 520 | 205 | 40 | 187 | 90 |

| 316L | 480 | 175 | 40 | 187 | 90 |

| 316Ti | 520 | 205 | 40 | 187 | 90 |

| 317L | 480 | 175 | 40 | 187 | 90 |

| 321 | 520 | 205 | 40 | 187 | 90 |

| 430 | 450 | 205 | 22 | 183 | 88 |

| 904L | 490 | 216 | 35 | ||

| 2205 | 640 | 25 | |||

| Chemical Composition | ||||||||||||

| Chemical Composition(%) | ||||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | ||

| 1Cr17Mn6Mi5N | 201 | 0.15 | 1.00 | 5.5-5.7 | 0.06 | 0.03 | 3.3-3.5 | 16-18 | _ | _ | 0.05-0.25 | |

| 1Cr18Mn8Mi5N | 202 | 0.15 | 1.00 | 7.5-10 | 0.06 | 0.03 | 4.0-6.0 | 17-19 | _ | _ | 0.05-0.25 | |

| 1Cr18Mn8Mi5N | 301 | 0.15 | 1.00 | 2.00 | 0.07 | 0.03 | 6.0-8.0 | 16-18 | _ | _ | 0.10 | |

| 0Cr18Ni9 | 304 | 0.07 | 1.00 | 2.00 | 0.035 | 0.03 | 8.1-10.0 | 17-19 | _ | _ | _ | |

| 0Cr18Ni9 | 309S | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 12.0-15.0 | 22-24 | _ | _ | _ | |

| 0Cr25Ni20 | 310S | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 19.0-22.0 | 24-26 | _ | _ | _ | |

| 0Cr17Ni12Mo2 | 316 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 10.0-14.0 | 16-18.5 | 2.0-3.0 | _ | _ | |

| 00Cr17Ni14Mo2 | 316L | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 12.0-15.0 | 16-18 | 2.0-3.0 | _ | _ | |

| 0Cr18Ni12Mo3Ti | 316Ti | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 11.0-14.0 | 16-19 | 2.5-3.5 | _ | _ | Ti≥5C |

| 0Cr18Ni12Mo3Ti | 317L | 0.03 | 1.00 | 2.00 | 0.035 | 0.03 | 11.0-15.0 | 18-20 | 3.0-4.0 | _ | _ | |

| 1Cr18Ni9Ti | 321 | 0.12 | 1.00 | 2.00 | 0.035 | 0.03 | 8.0-11.0 | 17-19 | _ | _ | _ | Ti5C-0.70 |

| 1Cr12 | 430 | 0.12 | 1.00 | 2.00 | 0.035 | 0.03 | 0.60 | 16-18 | _ | _ | _ | |

| 00Cr20Ni25Mo4.5Cu | 904L | 0.02 | 1.00 | 2.00 | 0.035 | 0.03 | 23.0-28.0 | 19-23 | 4.0-5.0 | 1.0-2.0 | 0.14-0.20 | |

| 00Cr2Ni5Mo3N | 2205 | 0.03 | 1.00 | 2.00 | 0.035 | 0.02 | 4.5-6.5 | 21-23 | 2.5-3.5 | _ | _ | |

| Stainless steel national standard _ stainless steel implementation standard _ national stainless steel grade comparison table | ||||||||||

No | China GB | Japan | United States | Korea | EU | India | Australia | Taiwan, China | ||

Old grade | New grade(07.10) | JIS | ASTM | UNS | KS | BS EN | IS | IS | CNS | |

Austenitic stainless steel | ||||||||||

1 | lCrl7Mn6Ni5N | 12Crl7Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Crl7Mn6Ni4N20 | 201-2 | 201 |

2 | lCrl8Mn8NI5N | 12Crl8Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

3 | lCrl7Ni7 | 12Crl7Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Crl7Ni7 | 301 | 301 |

4 | 0Crl8Ni9 | 06Crl9Nil0 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Crl8Ni9 | 304 | 304 |

5 | 00Crl9Nil0 | 022Crl9Nil0 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Crl8Nill | 304L | 304L |

6 | 0Crl9Ni9N | 06Crl9Nil0N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

7 | 0Crl9Nil0NbN | 06Crl9Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

8 | 00Crl8Nil0N | 022Crl9Nil0N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

9 | lCrl8Nil2 | 10Crl8Nil2 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

10 | 0Cr23Nil3 | 06Cr23Nil3 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

12 | 0Crl7Nil2Mo2 | 06Crl7Nil2Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Crl7Nil2Mo2 | 316 | 316 |

13 | 0Crl8Nil2Mo3Ti | 06Crl7Nil2Mo2Ti | SUS316TI | 316TI | S31635 | - | 1.4571 | 04Crl7Nil2MoTi20 | 316Ti | 316TI |

14 | 00Crl7Nil4Mo2 | 022Crl7Nil2Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Crl7Nil2Mo2 | 316L | 316L |

15 | 0Crl7Nil2Mo2N | 06Crl7Nil2Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

16 | 00Crl7Nil3Mo2N | 022Crl7Nil3Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

17 | 0Crl8Nil2Mo2Cu2 | 06Crl8Nil2Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

18 | 00Crl8Nil4Mo2Cu2 | 022Crl8Nil4Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

19 | 0Crl9Nil3Mo3 | 06Crl9Nil3Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

20 | 00Crl9Nil3Mo3 | 022Crl9Nil3Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

21 | 0Crl8Nil0Ti | 06Crl8NillTi | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Crl8Nil0Ti20 | 321 | 321 |

22 | 0Crl8NillNb | 06Crl8NillNb | SUS347 | 347 | S34700 | STS347 | 1.455 | 04Crl8Nil0Nb40 | 347 | 347 |

Austenitic-ferritic stainless steel (duplex stainless steel) | ||||||||||

23 | 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | 329J1 |

24 | 00Crl8Ni5Mo3Si2 | 022Crl9Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

0Crl8Nil0Ti ferritic stainless steel | ||||||||||

25 | 0Crl3AI | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Crl3 | 405 | 405 |

26 | - | 022CrllTi | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

27 | 00Crl2 | 022Crl2 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

28 | lCrl7 | 10Crl7 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Crl7 | 430 | 430 |

29 | lCrl7Mo | 10Crl7Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

30 | - | 022Crl8NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

31 | 00Crl8Mo2 | 019Crl9Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

Martensitic stainless steel | ||||||||||

32 | lCrl2 | 12Crl2 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

33 | lCrl3 | 12Crl3 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Crl3 | 410 | 410 |

34 | 2Crl3 | 20Crl3 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Crl3 | 420 | 420J1 |

35 | 3Crl3 | 30Crl3 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Crl3 | 420J2 | 420J2 |

36 | 7Crl7 | 68Crl7 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

Perforated Steel Sheets – 316 Stainless Steel | East King

Introducing East King Perforated Steel Sheets - the ultimate solution for your ventilation, filtration, and design needs. Engineered with precision and durability in mind, our perforated steel sheets offer countless benefits across diverse applications.

With strategically placed perforations, our steel sheets facilitate optimal airflow while maintaining structural integrity. Ideal for HVAC systems, our sheets ensure efficient air circulation, promoting comfort and productivity in any environment.

Whether it's sorting materials or filtering out impurities, East King perforated steel sheets excel in enhancing process efficiency. Their customizable hole patterns allow for precise filtration, ensuring superior performance in industrial settings.

Crafted from high-quality steel, East King perforated steel sheets are built to withstand the rigors of demanding applications. Their robust construction ensures long-lasting durability, making them a reliable choice for industrial and commercial projects.

Why Would You Choose These Perforated Steel Sheets?

Experience the unmatched performance and versatility of East King Perforated Steel Sheets. Solutions to meet your specific requirements, East King perforated steel sheets are available in a variety of sizes, hole patterns, and finishes. Delivers precision-engineered solutions to suit your needs.

Features and Benefits

Stainless steel - Type 316 austenitic (non magnetic)

High corrosion resistance

Selvedge border

Sheet size 500 x 500 mm

Thickness: 0.55 mm

Application

Chemical

Food

Photography and marine uses

East King-Perforated Steel Sheet, 3 mm Hole, 500 mm x 500 mm x 0.55 mm

This perforated steel sheet from East King offers a corrosion-resistant solution for your next construction project, whether it's boosting airflow around heated equipment or filtering lumpy liquids. It's commonly used in commercial and industrial settings such as the food manufacturing industry, photography studios, and marine environments.

The sheet is manufactured from type 316 austenitic chromium-nickel stainless steel, which means it's durable enough to withstand tough knocks and scrapes. This material remains strong at high temperatures and can tolerate common chemicals such as chloride ion solutions. For convenience, it has a selvedge border that doesn't require any extra finishing work before installation.

Due to manufacturing differences, there may be a variance of -5 mm/+10 mm on the width and length of each sheet. Metal sheets of this type are typically found on production lines and in agricultural applications.

Features and Benefits

Perforated form

Hole diameter of 3 mm

Hole layout of 60º

Made from stainless steel

Open area percentage of 33%

Pattern number 5

Suitable for chemical, food, photography and marine applications

Thickness of 0.55 mm

Length of 500 mm

Width of 500 mm

Copyright © 2019 East King Steel (Guangdong) Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist