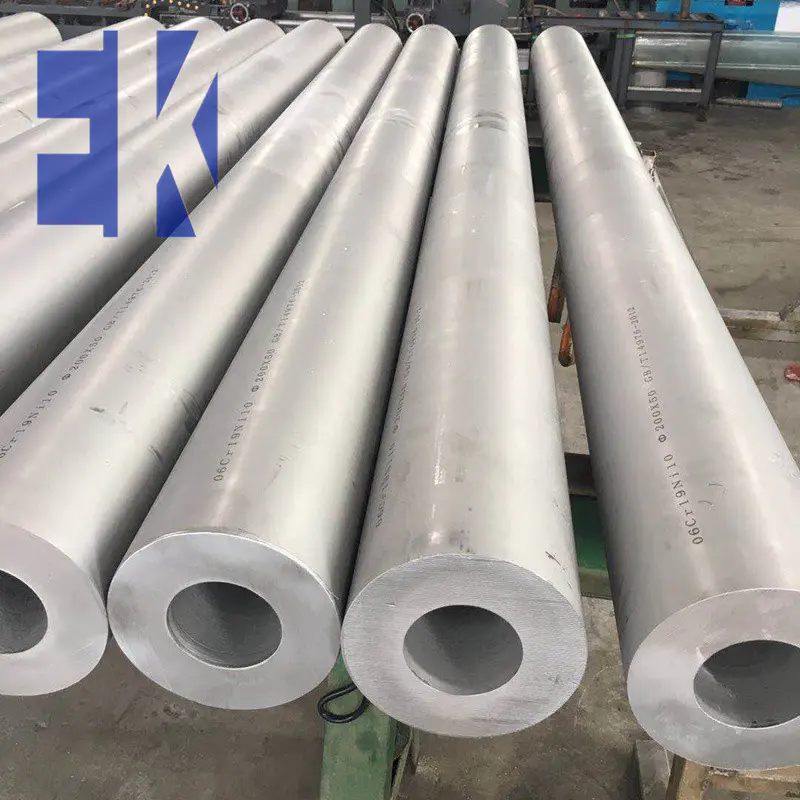

Making The Grade With Stainless Steel Tubing

by:East King

2020-08-29

Oil pipelines had been first used in Pennsylvania to connect an oil area to a railway station. This first pipeline spanned 6 miles and was made totally out of wrought iron. The next step to improve corrosion resistance was using zinc to galvanise pipes.

The addition of nitrogen additionally improves resistance to pitting corrosion and increases mechanical power. Thus, there are quite a few grades of stainless steel with varying chromium and molybdenum contents to swimsuit the setting the alloy should endure. Customers from different industries rely on Greenville Tube's quick supply of excessive-high quality merchandise. Seamless, welded and drawn tubing is manufactured at Greenville Tube, our Clarksville, Arkansas facility.

Nitronic 60, made by selective alloying with manganese, silicon, and nitrogen, has demonstrated a reduced tendency to gall. Type 304 and Type 316 stainless steels are unaffected weak bases such as ammonium hydroxide, even in high concentrations and at excessive temperatures.

The stringent production course of generates tubing that's microstructurally homogeneous throughout its OD and wall. In other purposes copper and copper alloys have been used extensively. Pipe bending is an important part within the formation of many several types of transport pipelines, like the ones which are used to carry such merchandise as oil, pure fuel, water and sewage. Before the invention of pipe bending for oil pipelines, oil was transported from oil wells to railway stations by horse in converted picket whiskey barrels. It is because of these picket whiskey barrels that we still measure oil by the barrel today.

The identical grades exposed to stronger bases similar to sodium hydroxide at high concentrations and high temperatures will likely experience some etching and cracking. Increasing chromium and nickel contents present increased resistance. All forms of stainless steel resist assault from phosphoric acid and nitric acid at room temperature. At excessive concentrations and elevated temperatures, assault will happen, and higher-alloy stainless steels are required.

Custom message