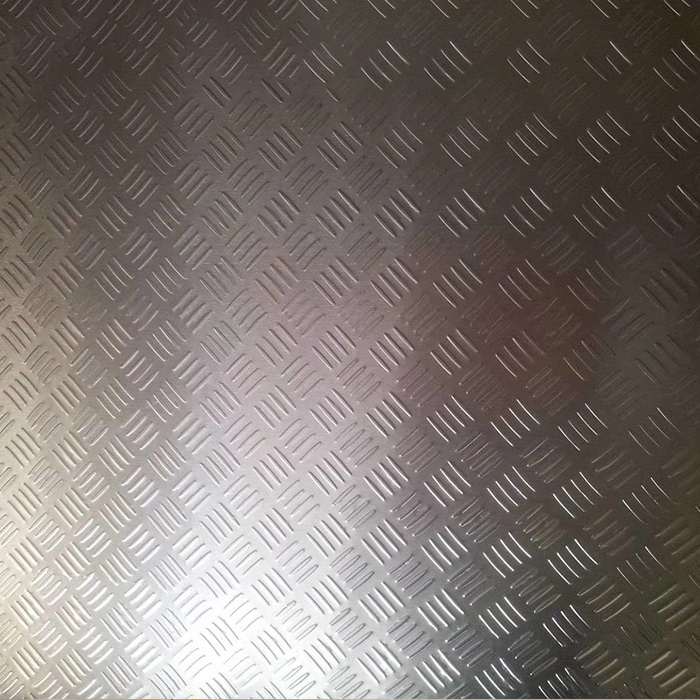

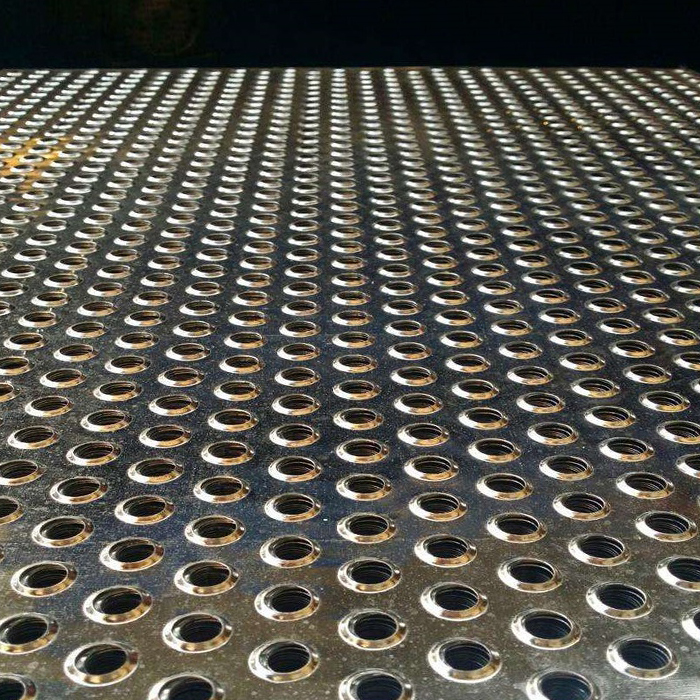

Description

All the products are cleaned and deburred before delivering or sending to do surface treatment so that products can look nice and exquisite. We do surface treatment as your demand. Such as: powder coating, brushing, polishing, galvanizing, chrome plating,etc.

Inspection Equipment

CMM, Calipers, Digital Caliper Gauge,Micro caliper, Thread Micro caliper, Pin gauge, Pass meter,,Caliper gauge,Coating Thickness Meter, etc.

| our service | capability |

| Sheet Metal Stamping | 1.Tolerance:±0.04mm 2.Material:Carbon steel,stainless steel,Brass&Copper ,aluminum aolly,etc 3.Material Thickness:0.1-12mm 4.Mould life time:500,000-1,000,000 Times 5.Machine & equipment:Punching machine,Press Machine 6.Drawing format: PDF, STP,STEP,DWG,DXF,IGS ,etc. |

| CNC Machining&Milling | 1.Tolerance:±0.001 2.Material:Carbon steel,stainless steel,Brass&Copper ,aluminum aolly,etc 3.Machine & equipment:4-Axis,5-axis CNC Machine,CNC Turning Machine, CNC Milling Machine,CNC Grinding Machine 4.Inspection Equipment:CMM,Projector,Hardness Tester 5.Drawing format: PDF, STP,STEP,DWG,DXF,IGS ,etc. |

| Custom Die casting | 1.Tolerance:CT6-CT8 2.Material:Aluminum aolly,Magnesium alloy,zinc alloy,Copper alloy,etc 3.Machine & equipment:Die casting Machine 4.Mould life time:80,000-150,000 times 5.Weight:0.1-25.0 KGS 6.Drawing format: PDF, STP,STEP,DWG,DXF,IGS ,etc. |

| Customized gravity casting | 1.Tolerance:CT6-CT10 2.Material:Aluminum aolly 、Carbon steel 、Iron and etc. 3.Machine & equipment:Casting machines 4.Mould life time:50,000-100,000 5.Weight:0.5-500.0 KGS 6Drawing format: PDF, STP,STEP,DWG,DXF,IGS ,etc. |

Available Mateials:

| Stainless Steel | S201 ,S301,S303,S304,S316,S410,S416 S430,S475 etc. |

| Steel: | Mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc |

| Aluminum | AL6061 ,AL6062,AL6063,AL6082,AL7075 ,AL5052 ,AL5083,AL3104.AL2024 AL1012 etc. |

| Brass&Copper | C1100, C1200 ,C2200, C2600, C7521, H59,H68 ,H80, H90 etc. |

| Spring Steel | 65Mn, 70Mn, 85Mn etc |

| Titanium | TA,TB,TC etc . |

| Plastic component | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE,Peek etc. |

| Material | Approach |

| Aluminum parts | Brushing, Polishing, Sandblasting, Anodizing, Nickel Plating, Chrome Plating, Bronze Plating, Copper Plating,PVD Plating, Dacromet, Passivation,Powder Coating etc. |

| Stainless Steel parts | Polishing, Brushing, PVD Plating, Nickel Plating, Chrome Plating, Powder Coating |

| Carbon Steel parts | Anodizing, Baking Varnish, Zinc Plating, Hot Dip Galvanizing, Chrome Plating, Electrophoresis Coating, Enamel Painting,Dacromet,Powder Coating, Heat Treatment etc. |

| Spring Steel part | Anodizing ,Powder Coating, Zinc Plating, Tin-plating, Nickel Plating Heat Treatment etc. |

| Brass&Copper parts | Polishing, Brushing, Oil Injection, PVD Plating, Passivation etc. |

| Plastic parts | Polishing, Painting ,Chrome plating ,Sandblasting ,laser engraving etc. |

Test Equipment:

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

Application :

Industry, Electrical industry, Mining industry, mechanical, metals, components for furniture, auto, machines etc.

FAQ:

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2:How long can i get the sample?

A2:Depends on your specific items,within 10-20 days is required generally.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical

proposals and a quotation to you, after your agreement, we produce for you.

Q4:What's kinds of information you need for quote?

A4:Kindly please provide the product drawing in PDF, STP,STEP,DWG,DXF,IGS ,etc

Copyright © 2019 East King Steel (Guangdong) Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist