Metal Manufacturing - Millstock Metal

by:East King

2020-05-19

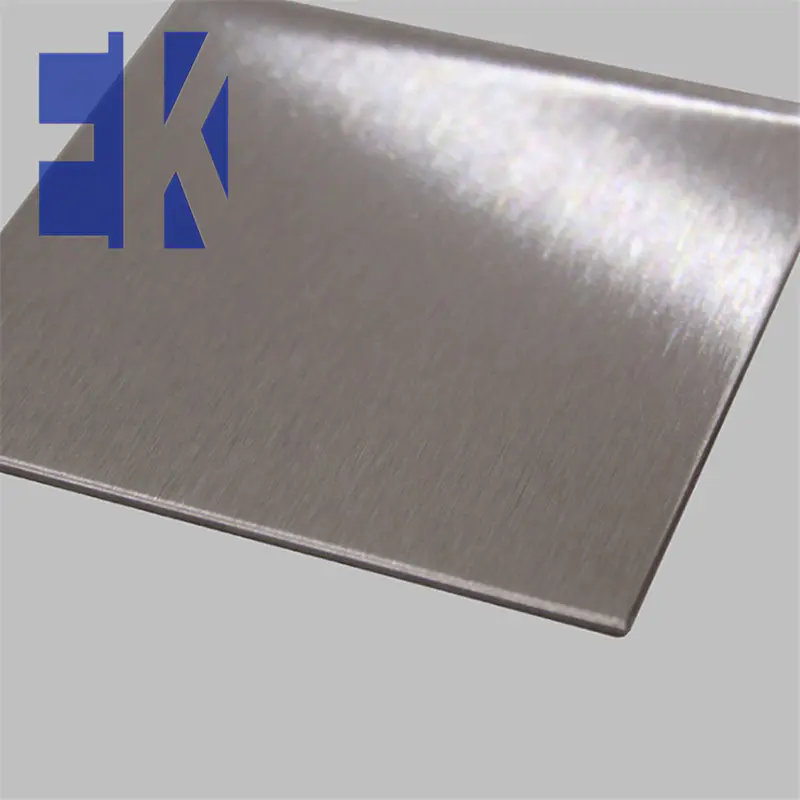

The stainless steel can become in selection of shapes, finishes and textures and also can be painted within a broad spectrum of color ways. The stainless steel is popularly utilized in the manufacturing of domestic and industrial appliances. The hard stainless steel materials and merchandise are highly resistant to stain, rust and frequently very difficult. The stainless steel is manufactured with number of processes depending on the type and grade of steel being produced. These grades are developed based on specific requirements. The heat treatment is given as per the desired look and feel and sort. The quality control is monitored while using whole manufacturing and fabricating process of stainless shiny steel.

How metal is purchased?

1. The raw metal is melted in any furnace.

2. The semi finished steel is heated, passed through giant rolls and formed into bar, wire, plate, list.

3. Then such stainless steel forms are heated and cooled giving strength towards metal one recommended temperature. The heating process depends on the type of steel. Low temperature produces high strength while high temperature produces lower strength and tougher material.

4. The cutting operations are performed using various methods like shearing, blanking, sawing, nibbling, flame cutting, plasma jet cutting for example.

5. Finally, the finishing is an important aspect of stainless steel processing. Affliction of finishing methods are applied according to required stainless steel materials. As well as annealing, descaling, buffing, tumbling, sandblasting, wire brushing and pickling devices.

6. To get final metal products, variety of welding and grinding methods are processed to give further framework. The Laser fusion welding is amongst the welding stainless steel methods. Precision grinding technique used and start to give dimensional appear to the models.

Laser Fusion Welding Service

The laser fusion welding is the effective process to produce deep penetration welds with minimum heat effective zones. Through laser fusion welding service, the unlike metals can simply be welded while producing reduced heat. This laser welding is very effective to cut hardest stainless steel materials without causing distortion. Laser fusion welding service gives powerful output with no different kinds of austenitic stainless steels with different thicknesses. Laser fusion welding service is highly capable for metals with various thermal conductivity and melting points.

Precision Grinding Service

Precision grinding service uses the capabilities of the materials. Precision grinding service works well with both metallic and non-metallic goods. Precision grinding processes are used to grind angles, faces, radius of expand into all the with surface, center, internal, external, jig, honing and CNC grinding in small, medium and big quantities. Precision grinding processes include CNC Swiss turning, CNC internal grinding, cylindrical grinding, rotary surface grinding, 5-axis CNC surface grinding etc.

Millstock Stainless mission will be always to offer the best choice and reliable stainless steel processing modules to meet industry even. This includes best laser fusion welding service and greatest quality of precision grinding service. Our stainless steel processing are welding stainless steel, Lean Duplex Laser Fusion Welded Sections, cut to length bar blanks, Turning & Boring, Forgings, Slitting and third party testing and inspection. Our skilled engineers cover each of metal processes and compliance with customer measures.

Custom message