Stainless Steel Coil And Strip

by:East King

2020-08-30

Therma 4828 is an austenitic warmth resisting stainless steel with improved oxidation resistance in temperatures up to 1000°C/1830°F. There is a slight susceptibility to embrittlement during steady operation atbetween 600–850°C/1110– 1560 °F.

NAS’s hot rolled coil product is on the market in annealed and pickled situation. The continuous mill plate product is on the market in coil form or sheet type, in extensive or slender width. Stainless Steel 17-7 A-313 is the next on the listing so far as pricing on stainless steel material types.

Ultra 654 SMO is the most corrosion-resistant stainless steel on the planet. A 7 % molybdenum, very high nitrogen alloyed austenitic product with excessive mechanical strength. A probably lean alternative to traditional wet-corrosion resistant nickel-primarily based alloys.

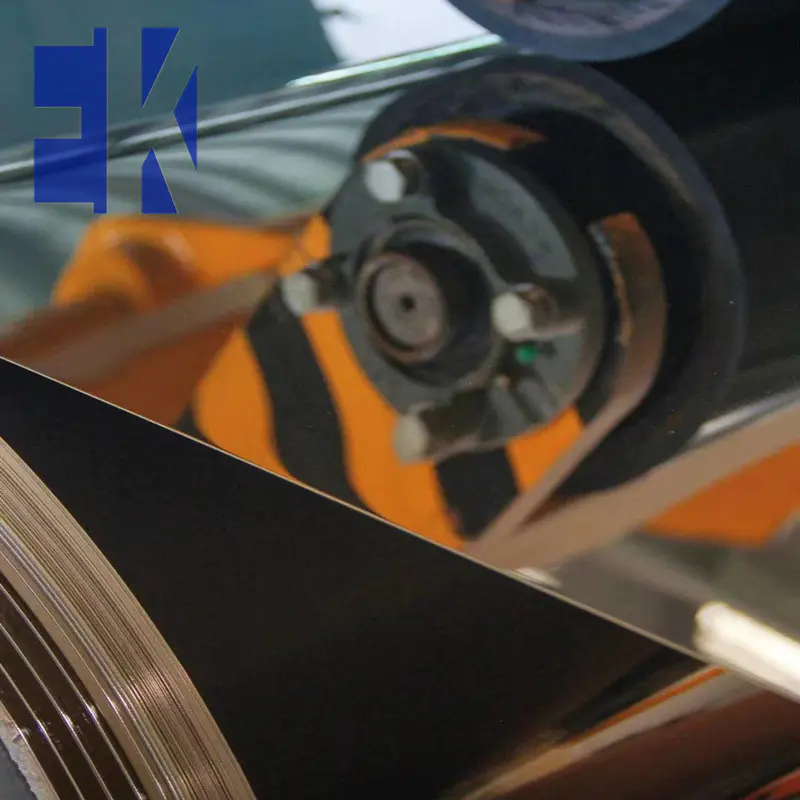

Hot-rolled coil is produced from semi-finished products , which are lowered to certain thicknesses by rolling and annealing and wound right into a roll. Hot-rolled steel is used e.g. for the manufacture of pipes, steel doors and tanks or is additional processed into chilly-rolled steel.

Therma 153 MA is an austenitic stainless steel with excellent oxidation and creep resistance in cyclic conditions that is finest employed in temperatures as much as 1050°C/1920°F. A precipitation hardening stainless steel with high strength and hardness, good corrosion resistance, and passable formability (depending on warmth remedy/condition). A 4.5% molybdenum, very high nitrogen alloyed austenitic stainless steel with wonderful corrosion resistance and excessive mechanical power.

It has a stronger tensile energy thus giving your spring more force/stiffness without truly changing the spring dimensions. It also can resist larger temperatures; it resists up to 650ºF (343ºC). When it involves steel coil spring design, there are a number of factors that must be considered. Some materials varieties are better underneath sure environments they usually even have different tensile strengths which is able to have an effect on your spring's pressure/stiffness at the time the spring is under its working loads. Therma 347H is an austenitic heat resisting stainless steel with glorious lengthy-term creep resistance at at 550–600°C/1020–1110°F and comparable moist corrosion resistance to Core 347/4550.

Since salt is corrosive, buildings positioned near the ocean or other salty places will profit from stainless steel evaporator coils. Many industries may also benefit from stainless steel evaporator coils, including chemical, meals & beverage, oil & gas, and pharmaceutical.

Emergent Coils supplies evaporator coils to satisfy your precise specs, often at a fraction of the cost of a new coil from the unique equipment producer . Our coils include a wide range of tube, fin and material options. We provide stainless steel coils in quite a lot of gauges from .002 to .135.

Custom message