Introduction:

Executive standard

Chinese standard

Hot rolled and forged stainless steel bars: GB/T1220-2007;

Cold processed stainless steel rod: GB4226-2009

American standard

Stainless steel bar and profile standard: ASTM A276-2011

General Standard ASTM A484-2011 for Stainless Steel Bars, Billets and Forgings

Standard ASTM A582-2011 for easy-to-process stainless steel rods

ASME SA276-2010

ASME SA484-2010

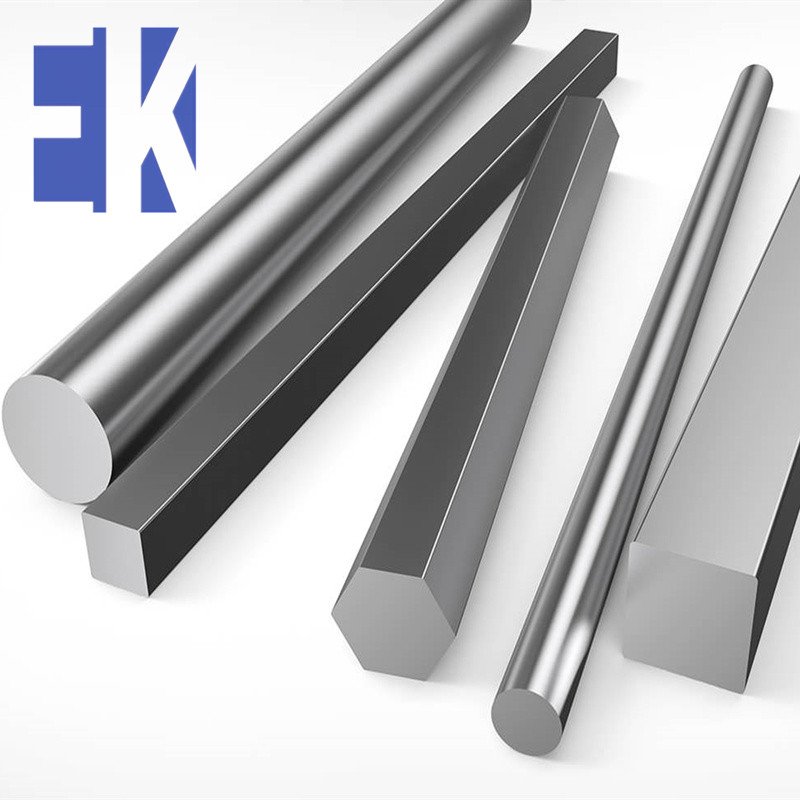

shape

Round steel, square steel, flat steel, hexagonal steel and octagonal steel are collectively referred to as stainless steel bars.

Specification material

Stainless steel rod specifications: hot-rolled and forged stainless steel rods with a size (diameter, side length, thickness or distance between sides) not greater than 250mm, above Ф1.0MM and below 250mm.

Stainless steel rod material: 304, 304L, 321, 316, 316L, 310S, 630, 1Cr13, 2Cr13, 3Cr13, 1Cr17Ni2, duplex steel, antibacterial steel and other materials! [1]

Scope of application

Stainless steel rods have broad application prospects and are widely used in hardware and kitchenware, shipbuilding, petrochemical, machinery, medicine, food, electric power, energy, building decoration, nuclear power, aerospace, military and other industries! Equipment used in seawater, chemical, dye, paper, oxalic acid, fertilizer and other production equipment; food industry, coastal facilities, ropes, CD rods, bolts, nuts.

Quality management: ISO9001: 2000 quality management system certification, production license, etc.!

Remarks: stainless steel rods of various materials and specifications can be customized non-standard.

Introduction of stainless steel rod material, application range and quality management

Material: 304, 304L, 321, 316, 316L, 310S, 630,

Common materials are 201, 202, 301, 304, 303, 316, 316L, 304L, 321, 2520, 1Cr13, 2Cr13, 3Cr13, duplex steel, antibacterial steel and other materials! The specification is expressed by diameter, such as "50" which means round steel with a diameter of 50 mm. Round steel is divided into three types: hot rolled, forged and cold drawn. The specification of hot-rolled round steel is 5.5-250 mm.

Applications: petroleum, electronics, chemical, pharmaceutical, textile, food, machinery, construction, nuclear power, aerospace, military and other industries!

Quality management: ISO9001: 2000 quality management system certification, production license, etc.!

Production Process 200 series—chromium-nickel-manganese austenitic stainless steel

300 series—chromium-nickel austenitic stainless steel

301—Good ductility, used for molded products. It can also be hardened by machine speed. Good weldability. Abrasion resistance and fatigue strength are better than 304 stainless steel.

302—The corrosion resistance is the same as 304, and the strength is better due to the relatively high carbon content.

303—By adding a small amount of sulfur and phosphorus, it can be processed more easily.

304—namely 18/8 stainless steel. The GB grade is 06Cr19Ni10.

309—Compared with 304, it has better temperature resistance.

316—After 304, the second most widely used steel grade, mainly used in food industry and surgical equipment, adding molybdenum element to obtain a special corrosion-resistant structure. Because it has better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. 18/10 grade stainless steel usually also meets this application level. [1]

According to the production process, stainless steel bars can be divided into three types: hot rolled, forged and cold drawn. The specifications of hot-rolled stainless steel round bars are 5.5-250 mm. Among them: 5.5-25mm small stainless steel round bars are mostly supplied in straight strips, often used as steel bars, bolts and various mechanical parts; stainless steel round bars larger than 25mm are mainly used to manufacture mechanical parts or seamless steel pipe billets .

Executive standard

National standard for stainless steel bars: GB/T14975-2002, GB/T14976-2002, GB/T13296-91

American Standard: ASTM A484/A484M, ASTM A213/213A, ASTM A269/269M

classification

According to the composition, it can be divided into Cr series (SUS400), Cr-Ni series (SUS300), Cr-Mn-Ni (SUS200) and precipitation hardening series (SUS600)Model 321—Except for the addition of titanium to reduce the risk of corrosion of the material welds, other properties are similar to 304.

400 series-ferritic and martensitic stainless steel

408—Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409—the cheapest model (British and American), usually used as car exhaust pipe, is a ferritic stainless steel (chrome steel).

410—Martensite (high-strength chromium steel), good wear resistance, poor corrosion resistance.

416—Add sulfur to improve the processing performance of the material.

420—"Cutting tool grade" martensitic steel, similar to the earliest stainless steel such as Brinell high chromium steel. It is also used for surgical knives, which can be very bright.

430—Ferritic stainless steel, for decoration, such as car accessories. Good formability, but poor temperature resistance and corrosion resistance.

440—High-strength cutting tool steel with slightly higher carbon content. After proper heat treatment, higher yield strength can be obtained. The hardness can reach 58HRC, which is among the hardest stainless steels. The most common application example is "razor blades". There are three commonly used models: 440A, 440B, 440C, and 440F (easy processing type).

500 series—heat-resistant chromium alloy steel.

600 series—Martensitic precipitation hardening stainless steel.

630—The most commonly used type of precipitation hardening stainless steel, usually called 17-4; 17% Cr, 4% Ni.

Copyright © 2019 East King Steel (Guangdong) Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist